ATEX certification sets a strict safety standard for equipment used in potentially explosive environments. Mining operations rely on explosion-proof headlamps mining to prevent ignition of hazardous gases or dust. ATEX compliance provides legal assurance and protects workers by ensuring every certified headlamp meets rigorous testing and design requirements. Companies that prioritize certified lighting solutions reduce risk and uphold regulatory standards.

Key Takeaways

- ATEX certification ensures mining headlamps are safe to use in explosive environments by preventing sparks and heat that could cause explosions.

- Mining companies must select headlamps that match the hazardous zone classification to protect workers and meet legal requirements.

- Certified headlamps carry both CE and Ex markings, which prove they passed strict safety tests and comply with European standards.

- Regular inspection, maintenance, and use of certified replacement parts keep headlamps reliable and maintain ATEX compliance.

- Training miners on safe headlamp use and hazard awareness builds a strong safety culture and reduces accident risks underground.

ATEX Certification and Explosion-Proof Headlamps Mining

Definition and Purpose of ATEX Certification

ATEX certification stands as a legal and technical requirement for equipment used in potentially explosive environments within the European Union. The ATEX Directive 2014/34/EU mandates that all equipment and protective systems intended for such atmospheres must meet strict health and safety standards before entering the EU market. Manufacturers must submit their products for rigorous testing by a notified body. Only after passing these tests can equipment receive the ‘Ex’ symbol, which signals its suitability for explosive atmospheres. The certification process also requires technical documentation, risk analysis, and a declaration of conformity. These steps ensure that every certified product, including explosion-proof headlamps mining, can operate safely in hazardous locations. The directive harmonizes compliance procedures across the EU, supporting both safety and the free movement of goods.

Note: ATEX certification is not optional for manufacturers and suppliers. It is a legal obligation that aims to prevent accidents and protect workers in industries exposed to explosive risks.

Why ATEX Certification Matters for Mining Headlamps

Mining environments present unique hazards, including the presence of methane gas, coal dust, and volatile chemicals. These substances can create explosive atmospheres, making safety-critical equipment essential. ATEX certification for explosion-proof headlamps mining serves several vital objectives:

- Prevents ignition sources in explosive atmospheres by ensuring equipment design eliminates sparks, flames, or excessive heat.

- Protects workers and the environment by reducing the risk of explosions caused by hazardous gases and dust.

- Requires rigorous testing, such as temperature resistance and spark suppression, to confirm safe operation in hazardous zones.

- Demonstrates a company’s commitment to safety management and the protection of human life and assets.

- Enhances operational reliability by ensuring equipment withstands harsh mining conditions, which reduces downtime and maintenance costs.

- Boosts confidence among employees and stakeholders by showing dedication to safety and quality.

ATEX certification specifically reduces explosion risks in underground mining. Equipment undergoes strict compliance with EU directives, which classify hazardous zones and require tailored safety standards. For example, historical mining disasters, such as the Monongah Mine Disaster, highlight the dangers of unprotected equipment. Certified explosion-proof headlamps mining help prevent similar incidents by eliminating ignition sources and ensuring reliable performance in methane- and dust-rich environments. The certification process includes ongoing quality assurance, temperature class limitations, and clear marking for gas and dust environments. These measures guarantee that headlamps and other mining equipment operate safely, protecting both workers and assets.

ATEX Directives and Legal Requirements

Key ATEX Directives for Mining Equipment

Mining operations in the European Union must comply with two main ATEX directives to ensure safety in explosive atmospheres.

- Directive 2014/34/EU (ATEX Equipment Directive): This directive governs the design, manufacturing, and certification of equipment for use in explosive environments. It applies directly to mining headlamps and requires conformity assessments, CE marking, and classification into specific equipment groups and categories.

- Directive 1999/92/EC (ATEX Workplace Directive): This directive focuses on worker safety. It requires employers to conduct risk assessments, implement protective measures, and provide training. Employers must also prepare Explosion Protection Documents to demonstrate compliance.

Failure to meet these directives can result in severe consequences. Mining companies may face fines, operational shutdowns, and reputational damage. Non-compliance also increases the risk of accidents, injuries, or fatalities.

Hazardous Area Zones and Their Impact on Headlamp Selection

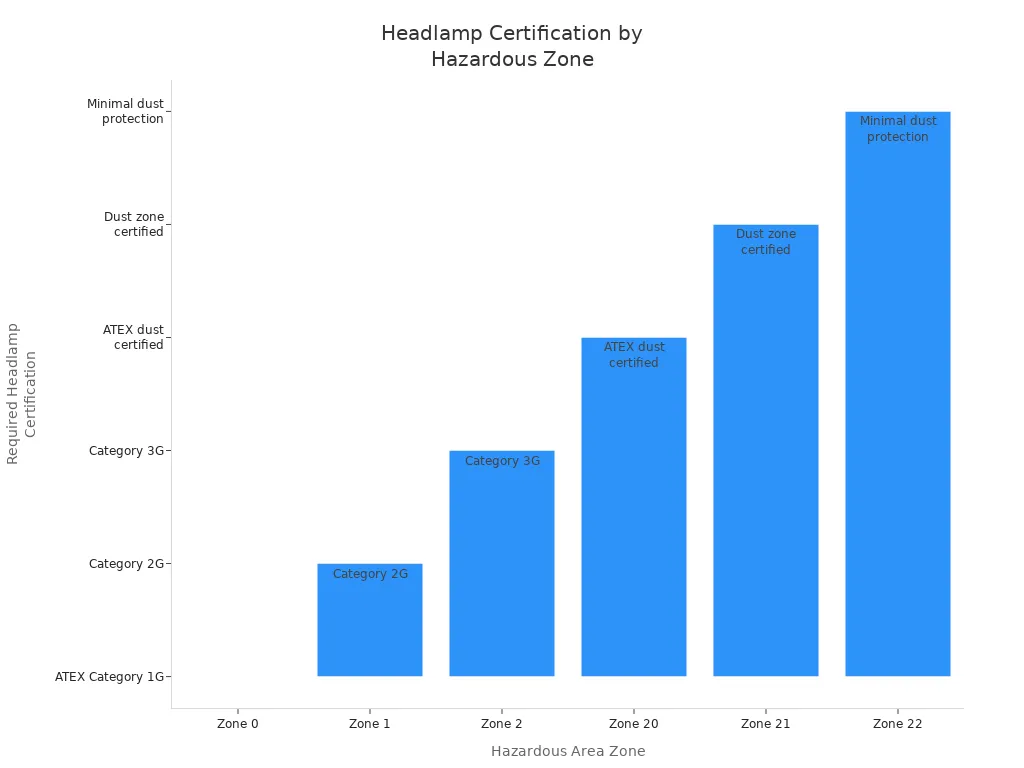

ATEX classifies hazardous areas in mining based on the likelihood and duration of explosive atmospheres. This classification directly impacts the selection of explosion-proof headlamps. The table below summarizes the zones and their requirements:

| Zone Type | Description of Hazardous Atmosphere Presence | Application in Mining | Impact on Headlamp Selection |

|---|---|---|---|

| Zone 0 (Gas) / Zone 20 (Dust) | Explosive atmospheres present continuously or for long periods | Highest risk areas with continuous methane or dust presence | Headlamps must be intrinsically safe, ATEX Category 1 certified |

| Zone 1 (Gas) / Zone 21 (Dust) | Explosive atmospheres likely during normal operations | Areas with frequent but not continuous presence | Headlamps require ATEX Category 2 certification |

| Zone 2 (Gas) / Zone 22 (Dust) | Explosive atmospheres unlikely or present for short periods | Lower risk zones with occasional presence | Headlamps can be ATEX Category 3 certified |

Mining companies must select headlamps that match the zone classification to ensure worker safety and regulatory compliance.

Equipment Groups and Categories Explained

ATEX divides equipment into two main groups.

- Group I: This group covers mining equipment, including headlamps. It addresses hazards from firedamp and combustible dust. Within Group I, two categories exist:

- M1: Equipment designed for locations where explosive atmospheres are likely during normal operation. These headlamps must provide the highest level of protection and continue to operate safely even when explosive gases or dust are present.

- M2: Equipment intended for areas where explosive atmospheres may occur occasionally. These headlamps must remain safe but can be switched off when a hazardous atmosphere is detected.

- Group II: This group applies to other industries with explosive atmospheres and uses categories 1, 2, and 3 based on risk levels.

The group and category classification determines the technical requirements, testing, and certification process for explosion-proof headlamps. Mining headlamps in Group I, especially those in category M1, must meet the strictest safety standards to protect workers underground.

ATEX Certification Process for Explosion-Proof Headlamps Mining

Risk Assessment and Hazard Identification

Mining companies must follow a structured approach to risk assessment and hazard identification before selecting explosion-proof headlamps mining. The process begins with identifying explosion hazards by analyzing flammable substances, oxidizers, and potential ignition sources. Teams then classify hazardous areas into zones, such as Zones 0, 1, and 2 for gases or Zones 20, 21, and 22 for dusts, based on how often explosive atmospheres occur. Documentation of this assessment appears in an Explosion Protection Document (EPD), which details protective measures and the rationale for equipment selection. Companies select equipment certified under ATEX Directive 2014/34/EU that matches the zone classification. Clear marking of hazardous zones informs all personnel. Regular employee training on explosion hazards and safe work procedures remains essential. Safe work systems, including hot work permits and operational controls, help prevent ignition sources.

Tip: Maintain comprehensive documentation and use only certified replacement parts to ensure ongoing compliance and safety.

Product Design and Intrinsic Safety Features

Manufacturers design explosion-proof headlamps mining with intrinsic safety as a top priority. These headlamps feature low electrical and thermal output to prevent ignition of gases, vapors, or dust. Temperature ratings ensure that surface temperatures stay below the ignition points of surrounding materials. Sealed construction with high ingress protection ratings, such as IP66 or IP67, protects against dust and water. Impact and chemical resistance help maintain safety integrity in harsh mining environments. Secure battery compartments prevent sparks or accidental exposure. Many models use rechargeable batteries with safe charging protocols. Adjustable mounting systems allow hands-free operation, and multiple beam modes provide versatile lighting for different mining tasks.

Testing, Evaluation, and Third-Party Certification

Manufacturers must submit explosion-proof headlamps mining to recognized laboratories for rigorous testing. The process includes examination of the device’s design and construction, followed by testing under both normal and abnormal operating conditions. Evaluation of performance data confirms adherence to technical specifications. Key aspects tested include temperature ratings, ingress protection, and the use of non-sparking, anti-static materials. Electrical protection measures prevent arcing or sparking. Only after passing all required tests does the product receive ATEX certification. The ATEX marking on each headlamp confirms compliance with EU safety requirements and suitability for hazardous mining zones.

Technical Documentation, CE, and Ex Marking

Manufacturers must prepare comprehensive technical documentation for every explosion-proof headlamp intended for mining. This documentation serves as proof that the product meets all ATEX requirements. It includes detailed design drawings, risk assessments, test reports, and user instructions. The technical file must remain available for inspection by authorities for at least ten years after the last unit is placed on the market.

The CE marking acts as a visible declaration that the headlamp complies with all relevant European directives, including ATEX. Before affixing the CE mark, manufacturers must complete a conformity assessment. This process involves:

- Compiling the technical documentation.

- Undergoing third-party testing by a notified body.

- Issuing an EU Declaration of Conformity.

Note: The CE mark alone does not guarantee explosion protection. Only products with both CE and Ex markings meet the strict requirements for hazardous environments.

The Ex marking provides specific information about the explosion protection features of the headlamp. It appears directly on the product and in the user manual. The Ex code includes details such as equipment group, category, protection method, and temperature class. For example:

| Marking Example | Meaning |

|---|---|

| Ex I M1 | Group I (mining), Category M1 (highest safety) |

| Ex II 2G Ex ib IIC T4 | Group II, Category 2, Gas, Intrinsic safety, Gas group IIC, Temp class T4 |

Mining companies should always verify both CE and Ex markings before purchasing headlamps. These markings ensure the equipment meets legal and safety standards for explosive atmospheres. Proper documentation and marking support traceability, regulatory compliance, and worker safety.

Selecting ATEX-Certified Explosion-Proof Headlamps Mining

How to Identify Genuine ATEX-Certified Headlamps

Mining companies face significant risks from counterfeit or uncertified lighting products. To ensure safety, teams must verify that each headlamp carries authentic ATEX and Ex markings. These markings should appear clearly on the product and in the user manual. The CE mark must also be present, confirming compliance with European directives.

Common counterfeit risks in the explosion-proof lighting market include:

- Products lacking proper certification or documentation

- Fake or altered certification labels

- Unreliable suppliers offering uncertified equipment

Procurement teams should request original certificates and cross-check serial numbers with the manufacturer or notified body. Reliable suppliers provide transparent documentation and traceable product histories. Only purchase explosion-proof headlamps mining from trusted sources with a proven record in hazardous area lighting.

Essential Features for Mining Safety

Explosion-proof headlamps designed for mining must offer robust safety features. Key attributes include:

- Intrinsic safety design to prevent sparks or excessive heat

- High ingress protection (IP66 or higher) for dust and water resistance

- Durable construction to withstand impacts and harsh chemicals

- Secure, sealed battery compartments to avoid accidental ignition

- Rechargeable batteries with safe charging protocols

- Adjustable mounting systems for hands-free use

- Multiple lighting modes for different mining tasks

These features ensure reliable performance in hazardous environments and support compliance with ATEX standards.

Practical Tips for Compliance and Safe Operation

Mining operations must follow best practices to maintain safety and regulatory compliance. The table below summarizes essential steps:

| Aspect | Best Practice Details |

|---|---|

| Equipment Selection | Use ATEX-certified headlamps rated for the correct mining zone and category. |

| Installation | Employ qualified personnel; follow manufacturer instructions; ensure proper grounding. |

| Maintenance & Inspection | Schedule regular inspections; address any wear or damage immediately. |

| Documentation | Keep detailed records of equipment, certifications, and maintenance. |

| Training & Safety | Train employees on hazards, proper use, and maintenance; promote a safety-first culture. |

| Replacement Parts | Use only certified replacement parts. |

| Cleaning Procedures | Clean headlamps with mild soap and a damp cloth; avoid harsh chemicals. |

Tip: Never modify or tamper with explosion-proof headlamps mining. Always use manufacturer-recommended batteries and chargers to preserve certification and safety.

Maintaining Compliance with Explosion-Proof Headlamps Mining

Inspection and Maintenance Best Practices

Mining operations depend on reliable lighting to ensure worker safety in hazardous environments. Regular inspection and maintenance of headlamps play a critical role in upholding ATEX compliance. Companies should establish a comprehensive maintenance program that includes scheduled inspections, thorough testing, and professional servicing. These inspections must cover all critical components, such as battery compartments, seals, switches, and light sources. Teams should follow manufacturer recommendations and adjust inspection intervals based on operational conditions.

Proper documentation supports compliance. Maintenance logs should record inspection dates, findings, and any corrective actions taken. Professional servicing by qualified technicians helps identify potential issues before they compromise safety. Companies must replace worn or damaged parts only with certified components to maintain the integrity of the equipment.

Tip: Consistent maintenance not only extends the lifespan of headlamps but also ensures ongoing compliance with ATEX standards.

Training and User Responsibilities

Effective training programs equip miners with the knowledge and skills needed to use headlamps safely in explosive atmospheres. Training should include:

- Hazard awareness related to explosive environments

- Instruction on the correct use of ATEX-certified equipment

- Clear safety protocols for installation, inspection, and maintenance

- Emergency preparedness, including roles during incidents

- Regular updates and drills to reinforce emergency response plans

Users have specific responsibilities when selecting and operating headlamps. They must choose intrinsically safe models suitable for their work environment and ensure compliance with relevant certifications. Selecting the appropriate brightness and adjustable features supports task-specific needs. Workers should verify that battery life matches their shift duration to avoid interruptions. Hands-free operation enhances safety and efficiency, especially in confined spaces. Awareness of hazardous conditions and the role of headlamps in preventing accidents remains essential.

| User Responsibility | Description |

|---|---|

| Select certified headlamps | Ensure equipment meets safety standards for explosive atmospheres |

| Match headlamp to environment | Choose models appropriate for specific mining zones and tasks |

| Monitor battery life | Confirm sufficient power for the entire work period |

| Use hands-free solutions | Maintain operational efficiency and safety |

| Stay alert to hazards | Recognize risks and respond quickly in emergencies |

Regular training and clear user responsibilities build a strong safety culture and help prevent accidents in mining operations.

ATEX-certified headlamps play a vital role in mining safety and regulatory compliance. Certified equipment reduces legal risks and ensures reliable performance in hazardous environments. Mining operators should:

- Select headlamps with clear ATEX and Ex markings.

- Schedule regular inspections and use only certified replacement parts.

- Provide ongoing training for all users.

Proper selection and maintenance of compliant headlamps protect both workers and assets.

FAQ

What does ATEX certification mean for mining headlamps?

ATEX certification confirms that a headlamp meets strict European safety standards for explosive atmospheres. Certified products display both CE and Ex markings, ensuring safe operation in hazardous mining environments.

How can miners verify a headlamp’s ATEX certification?

Miners should check for CE and Ex markings on the headlamp and review the manufacturer’s documentation. Reliable suppliers provide original certificates and traceable product histories.

Tip: Always request certification documents before purchasing equipment.

Which features make a headlamp suitable for mining safety?

Key features include intrinsic safety design, high ingress protection (IP66 or higher), durable construction, sealed battery compartments, and rechargeable batteries. Adjustable mounting and multiple lighting modes support various mining tasks.

| Feature | Benefit |

|---|---|

| Intrinsic safety | Prevents ignition |

| High IP rating | Blocks dust and water |

| Durable build | Withstands harsh use |

Post time: Aug-12-2025

fannie@nbtorch.com

fannie@nbtorch.com +0086-0574-28909873

+0086-0574-28909873