A durable industrial flashlight reduces repair needs, extends its usable life, and limits downtime. Regular maintenance routines play a key role in keeping equipment reliable and cost-effective. Companies that prioritize predictive maintenance see unplanned downtime drop to 5.42%, compared to 8.43% for reactive approaches. The table below shows how maintenance strategies affect downtime:

| Maintenance Type | Unplanned Downtime Percentage |

|---|---|

| Predictive Maintenance | 5.42% |

| Reactive Maintenance | 8.43% |

| Planned Maintenance | 7.96% |

Industrial flashlight durability brings real savings by lowering the frequency of repairs and replacements.

Key Takeaways

- Choose durable industrial flashlights with impact-resistant, waterproof, and corrosion-resistant features to reduce repairs and replacements.

- Perform regular preventive maintenance like cleaning and inspections to catch problems early and extend flashlight lifespan.

- Use rechargeable batteries and monitor power levels to save money and avoid unexpected outages during work.

- Organize inventory and schedule maintenance with software tools to keep flashlights ready and reduce downtime.

- Train staff on proper flashlight care, storage, and handling to prevent damage and maintain high performance.

The Impact of Industrial Flashlight Durability on Maintenance Costs

The Cost of Using Low-Quality Flashlights

Low-quality flashlights often lead to frequent breakdowns and unexpected failures. These devices typically lack robust construction, making them vulnerable to drops, water exposure, and harsh chemicals. When a flashlight fails during a critical task, workers face delays and may need to halt operations until a replacement arrives. This downtime increases labor costs and disrupts workflow. Companies that rely on inferior lighting solutions also spend more on frequent replacements and emergency repairs. Over time, these expenses add up, straining maintenance budgets and reducing overall productivity.

Tip: Investing in quality from the start prevents hidden costs associated with repeated failures and emergency purchases.

How Durability Minimizes Repairs and Replacements

Industrial flashlight durability plays a crucial role in minimizing repair and replacement incidents. Manufacturers achieve this durability by using rugged materials and advanced engineering. For example, impact-resistant designs protect internal components from damage caused by drops or collisions. High Ingress Protection (IP) ratings, such as IP67 or IP68, shield the flashlight from dust and water, ensuring reliable performance in demanding environments. Corrosion-resistant materials like high-grade aluminum or coated plastics withstand exposure to chemicals and gases commonly found in industrial settings.

The adoption of LED technology further enhances durability. LED flashlights offer longer battery life, greater energy efficiency, and a longer lifespan compared to traditional xenon models. This reduces the frequency of replacements and lowers energy consumption. Specialized batteries and components allow these flashlights to operate under extreme temperatures, making them suitable for a wide range of industrial applications. Certifications such as Class 2 Division 1 confirm that the flashlight meets strict safety and durability standards, reducing the risk of failure in hazardous environments.

Key durability features that reduce maintenance costs:

- Impact-resistant construction absorbs shocks and prevents internal damage.

- Waterproof and dustproof designs maintain functionality in harsh conditions.

- Corrosion-resistant materials extend the lifespan of the flashlight.

- LED technology delivers robust performance and reduces energy costs.

- Easy maintenance features, such as tool-free battery replacement, minimize downtime.

Preventive Maintenance and Its Role in Cost Reduction

Preventive maintenance significantly lowers repair costs for industrial flashlights. Regular inspections help identify potential issues before they escalate into major problems. By scheduling maintenance during planned downtime, organizations avoid unexpected disruptions and keep operations running smoothly. Maintenance teams can prepare by gathering documentation and ensuring all necessary tools are available. Detailed inspections reveal early signs of wear or malfunction, allowing for timely intervention.

Proper preventive maintenance can reduce overall maintenance costs by 30-50%, as seen in other industrial equipment. This approach extends the lifespan of flashlights and improves asset reliability. Maintenance planning and resource allocation become more efficient, reducing the likelihood of emergency repairs. Computerized maintenance management systems (CMMS) automate scheduling and tracking, ensuring that no inspection is missed.

- Preventive maintenance inspections detect problems early.

- Inspections reduce breakdowns and downtime.

- Maintenance planning improves with regular inspections.

- Asset reliability increases, extending equipment lifespan.

Organizations that prioritize industrial flashlight durability and implement preventive maintenance routines experience fewer failures, lower repair costs, and greater operational efficiency.

Essential Features for Industrial Flashlight Durability

Impact-Resistant and Waterproof Construction

Industrial environments demand flashlights that can withstand tough conditions. Manufacturers use materials like aircraft-grade aluminum alloy and titanium to create bodies that resist dents, wear, and corrosion. These metals provide a strong barrier against accidental drops and rough handling. Many models undergo rigorous drop testing to ensure they survive impacts common in heavy-duty workplaces.

Waterproofing also plays a critical role. High IP ratings, such as IP67 and IP68, indicate that a flashlight can resist dust and water intrusion. For example, some models remain functional after submersion in water up to one meter for thirty minutes. The following table highlights how leading flashlights perform in independent tests:

| Flashlight Model | Waterproof Rating | Impact Resistance | Material & Features |

|---|---|---|---|

| Fenix PD40R V3 | IP68 (submersible to 6.5 ft for 30 min) | 1.5 meter impact resistance | Titanium-coated body clip, tail stand |

| Streamlight Strion 2020 | IPX7 (waterproof to 1 meter) | 2-meter impact resistance | Machined 6000 series aluminum, anodized finish |

These features ensure reliable operation in wet, dusty, or hazardous environments.

High-Performance LED and Power Display

Modern industrial flashlights rely on high-performance LED systems. LEDs deliver superior brightness, longer service life, and greater energy efficiency compared to older xenon or HID technologies. For instance, high-power LEDs can reach up to 100,000 hours of service life, while traditional xenon bulbs last around 2,000 hours. LEDs also provide instant illumination and maintain consistent brightness throughout their lifespan.

Key advantages of high-performance LEDs include:

- Higher system efficiency, often exceeding 50 lumens per watt.

- Shock resistance, making them ideal for outdoor and industrial use.

- No ultraviolet or infrared emissions, reducing risk of damage to sensitive materials.

- Gradual dimming at end of life, rather than sudden failure.

A numerical power display further enhances usability. Workers can monitor remaining battery life at a glance, reducing the risk of unexpected outages during critical tasks.

Rechargeable vs. Disposable Battery Systems

Battery choice affects both durability and cost. Rechargeable systems offer significant savings over time by reducing the need for frequent battery replacements. These systems also support sustainability goals by minimizing waste. Disposable batteries may provide convenience in remote locations, but they increase long-term expenses and maintenance needs.

Many industrial flashlights now feature built-in rechargeable batteries with USB charging ports. This design allows for quick recharging and less downtime. Some models even double as power banks, providing emergency charging for other devices. By selecting flashlights with robust rechargeable systems, organizations can further reduce maintenance costs and improve operational efficiency.

Ergonomic Design and Multi-Functionality

Industrial flashlights must do more than provide light. Ergonomic design ensures that workers can use these tools comfortably for extended periods. Manufacturers focus on grip shape, weight distribution, and button placement. A well-balanced flashlight reduces hand fatigue and allows for precise control, even when users wear gloves. Textured surfaces and anti-slip coatings further enhance handling in wet or oily environments.

Multi-functionality stands as a key feature in modern industrial flashlights. Adjustable beam patterns, such as flood and spot modes, allow users to switch between wide-area illumination and focused inspection. This flexibility supports a range of tasks, from reading schematics to scanning large workspaces. Some models include zoomable lenses, enabling workers to adapt quickly to changing conditions.

Note: Ergonomic studies and workplace safety reports highlight that advanced lighting features in flashlights improve employee well-being by reducing eye strain and enhancing hazard detection. For example, a CDC study found that LED lighting reduced glare discomfort by 45% and improved detection of floor trip hazards by 23.7%. These improvements help workers avoid mistakes and maintain productivity.

Flashlights with built-in power displays, safety hammers, or emergency power bank functions add further value. Workers can monitor battery life, break glass in emergencies, or charge mobile devices without carrying extra equipment. These features reduce the need for multiple tools, streamlining maintenance kits and lowering the risk of lost or damaged gear.

A table below summarizes key ergonomic and multi-functional features:

| Feature | Benefit |

|---|---|

| Textured Grip | Prevents slips, improves comfort |

| Adjustable Beam | Enhances visibility for various tasks |

| Power Display | Prevents unexpected power loss |

| Safety Hammer | Adds emergency capability |

| Power Bank Function | Supports device charging in the field |

By prioritizing ergonomic design and multi-functionality, organizations equip their teams with tools that boost efficiency, reduce errors, and support long-term cost savings.

Maintenance Routines to Maximize Flashlight Lifespan

Cleaning and Inspection Best Practices

Routine cleaning and inspection keep industrial flashlights in peak condition. Dirt, dust, and moisture can build up on the lens and body, reducing light output and causing corrosion. Workers should use a soft, lint-free cloth to wipe down the flashlight after each use. For stubborn grime, a mild soap solution works well. Avoid harsh chemicals that may damage seals or finishes.

Inspection should focus on key areas:

- Lens and Reflector: Check for scratches or cloudiness that can affect beam quality.

- Seals and O-rings: Look for cracks or wear that could compromise waterproofing.

- Switches and Buttons: Ensure smooth operation and no sticking.

- Body and Housing: Examine for dents, cracks, or signs of corrosion.

Tip: Schedule inspections at regular intervals, such as weekly or monthly, depending on usage frequency. Early detection of wear prevents costly repairs and unexpected failures.

A simple inspection checklist helps teams stay consistent:

| Inspection Point | What to Look For | Action Needed |

|---|---|---|

| Lens/Reflector | Scratches, dirt, cloudiness | Clean or replace |

| Seals/O-rings | Cracks, dryness, wear | Lubricate or replace |

| Switches/Buttons | Sticking, unresponsive | Clean or repair |

| Body/Housing | Dents, corrosion, cracks | Repair or replace |

Battery Care and Safe Replacement

Proper battery care extends both battery and flashlight lifespan. Industrial flashlights often use advanced rechargeable batteries, which require careful handling. Workers should always follow manufacturer guidelines for charging and replacement.

Battery performance and safety depend on rigorous testing. Manufacturers use several tests to ensure reliability:

- Capacity testing measures how much energy the battery can store and deliver.

- Efficiency testing checks how well the battery converts stored energy into usable power.

- Cycling testing evaluates the battery’s ability to handle repeated charging and discharging.

- Temperature testing assesses performance in extreme heat or cold.

- Aging testing monitors battery health over time.

- Mechanical stress testing subjects batteries to vibration and shock.

- Environmental testing simulates humidity and temperature changes.

- Abuse testing determines resistance to impacts and punctures.

- Life cycle testing examines durability throughout the battery’s operational life.

Technicians rely on specialized tools for battery maintenance:

- Battery testers measure voltage, current, and capacity.

- Battery cyclers perform repeated charge/discharge cycles.

- Battery analyzers check chemical composition and temperature.

- Battery management systems (BMS) monitor charging and discharging.

- Environmental chambers simulate different climates.

- Battery testing fixtures secure batteries during tests.

Safety standards such as UN 38.3, IEC 62133, UL 1642, and UL 2054 set strict requirements for battery handling and replacement. These standards ensure batteries withstand vibration, shock, and temperature extremes. Compliance with CE marking and RoHS directives further guarantees environmental and user safety.

Note: Always replace batteries in a clean, dry environment. Dispose of old batteries according to local regulations to prevent environmental harm.

Proper Storage to Prevent Damage

Correct storage practices protect flashlights from unnecessary wear and extend their service life. Workers should store flashlights in a cool, dry place away from direct sunlight and extreme temperatures. High humidity can cause corrosion, while excessive heat may degrade battery performance.

Key storage guidelines include:

- Store flashlights with batteries removed if not used for extended periods.

- Use protective cases or wall-mounted racks to prevent drops and impacts.

- Keep flashlights away from chemicals or solvents that could damage seals or finishes.

- Label storage locations for easy inventory tracking.

A well-organized storage system reduces the risk of loss and ensures flashlights remain ready for use. Teams that follow these routines experience fewer breakdowns and enjoy longer-lasting equipment.

Callout: Consistent cleaning, careful battery management, and proper storage form the foundation of a cost-effective maintenance program for industrial flashlights.

Scheduled Maintenance and Record Keeping

Scheduled maintenance forms the backbone of a reliable industrial flashlight program. Organizations that implement structured maintenance routines see fewer unexpected failures and lower repair costs. Maintenance teams use scheduling models, often powered by a Computerized Maintenance Management System (CMMS), to plan inspections and servicing at optimal intervals. This approach prevents both over-maintenance and neglect, ensuring each flashlight receives attention exactly when needed.

A well-organized maintenance schedule offers several advantages:

- Reduces downtime by catching issues before they cause failures.

- Controls costs by avoiding unnecessary repairs and replacements.

- Improves resource allocation, allowing teams to focus on high-priority tasks.

- Enhances safety by ensuring all equipment remains in peak condition.

Maintenance managers rely on record-keeping to track every action taken on each flashlight. Detailed logs document inspections, cleanings, battery replacements, and repairs. These records provide a clear history for each unit, making it easy to identify recurring problems or units that require more frequent attention. Audit logs within a CMMS centralize this information, supporting data-driven decisions and compliance with safety standards.

Tip: Consistent record-keeping helps organizations spot trends, such as frequent battery replacements or repeated switch failures. Addressing these patterns early can prevent larger issues and reduce long-term costs.

Many industries have demonstrated the benefits of scheduled maintenance and thorough record-keeping. For example, a water treatment plant uses scheduled inspections to maintain water quality and prevent equipment breakdowns. Municipal governments optimize street maintenance resources by analyzing audit logs, ensuring efficient use of staff and materials. Across sectors, organizations report improved safety, reduced waste, and better operational efficiency after adopting CMMS-driven maintenance programs.

A simple maintenance record template can streamline the process:

| Date | Flashlight ID | Task Performed | Technician | Notes |

|---|---|---|---|---|

| 2024-06-01 | FL-102 | Battery Replaced | J. Smith | Battery at 10% |

| 2024-06-08 | FL-104 | Lens Cleaned | A. Brown | Minor dust removed |

| 2024-06-15 | FL-102 | Full Inspection | J. Smith | No issues found |

By maintaining accurate schedules and records, organizations ensure every flashlight delivers reliable performance. This proactive approach not only extends equipment lifespan but also supports a safer, more efficient workplace.

Troubleshooting and Cost-Effective Repairs

Common Issues and Quick Solutions

Industrial flashlights may encounter several common problems during their service life. Users often report issues such as flickering lights, unresponsive switches, or reduced brightness. Dirt on the lens or battery contacts can cause many of these problems. Cleaning the lens and checking the battery terminals often restores full function. When a flashlight fails to power on, technicians should inspect the battery for charge and proper installation. Replacing worn-out O-rings can resolve waterproofing failures.

A structured diagnostic process helps identify the root cause efficiently. Many service centers, like Micro Center, follow a step-by-step approach:

- Begin with a visual inspection and discuss symptoms with the user.

- Conduct comprehensive hardware testing to pinpoint faults.

- Tailor diagnostics based on whether the device powers on or not.

- Communicate findings and repair options clearly.

- Provide transparent cost estimates before starting repairs.

This method reduces unnecessary repairs and ensures cost-effective solutions.

Deciding When to Repair or Replace

Technicians must decide whether to repair or replace a flashlight based on several factors. If the cost of repair approaches the price of a new unit, replacement often makes more sense. Frequent breakdowns or recurring issues signal that the flashlight may have reached the end of its useful life. Transparent repair cost estimates, including itemized parts and labor, help organizations make informed decisions. Quick diagnostics and same-day service options minimize downtime and keep teams productive.

Tip: Always compare the total repair cost with the replacement cost. Consider the age and reliability of the flashlight before making a decision.

Using Quality Replacement Parts

Using high-quality replacement parts ensures that repaired flashlights meet industrial standards for durability and performance. Manufacturers subject parts to rigorous quality assurance tests, including vibration, thermal cycling, drop, and impact testing. These tests verify that components withstand harsh environments and daily wear.

| Test Type | Purpose |

|---|---|

| Vibration Testing | Simulates transport and continuous use |

| Thermal Cycling | Tests response to temperature extremes |

| Drop and Impact Testing | Assesses resilience to accidental drops |

| Accelerated Aging | Predicts long-term durability |

| Humidity/Environmental | Evaluates corrosion resistance |

| Immersion Testing | Verifies water resistance (IP standards) |

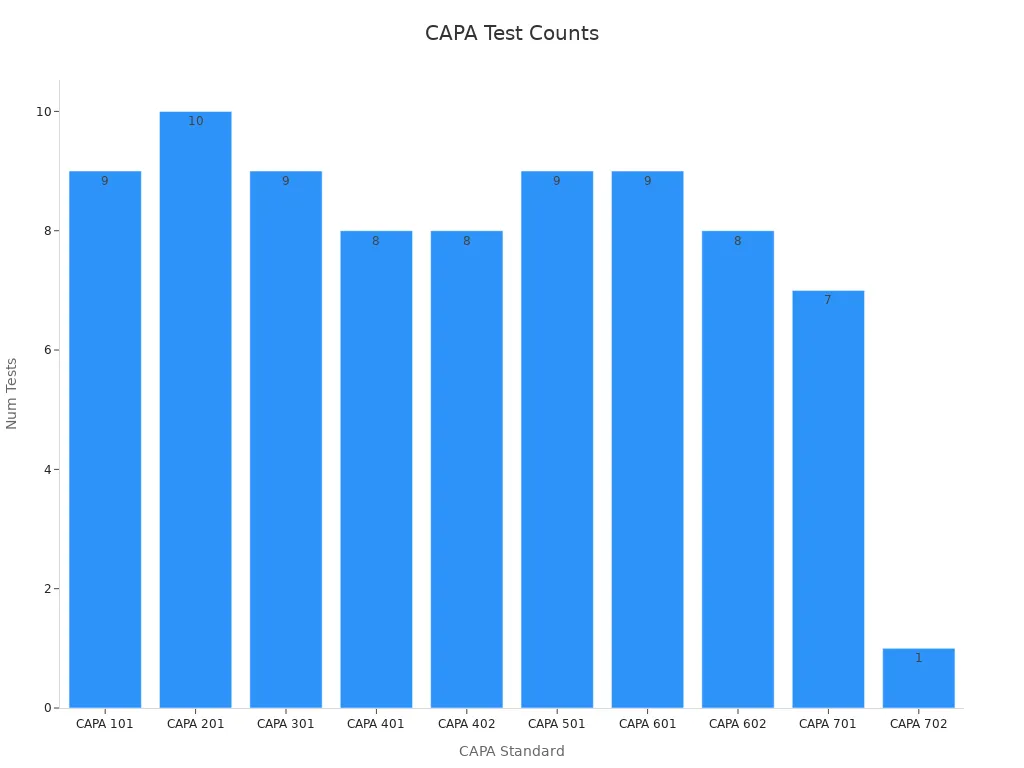

Quality assurance standards, such as CAPA 301 for lighting, require tests for illumination, projected life, and materials. These measures help organizations avoid repeated failures and ensure long-term reliability after repairs.

Managing Multiple Industrial Flashlights in Organizations

Inventory Tracking and Labeling Systems

Organizations that manage large numbers of industrial flashlights must prioritize effective inventory tracking. A well-organized inventory system prevents costly mistakes and improves operational safety. For example, a forgotten flashlight in an F-35 fighter jet caused nearly $4 million in damage, highlighting the importance of precise tool management. Poor inventory practices can lead to lost equipment, hazardous environments, and increased costs.

Many organizations implement these best practices:

- Organize flashlights by type, usage frequency, and criticality.

- Conduct regular audits—daily, monthly, or quarterly—to maintain accuracy.

- Maintain detailed inventory lists, recording item attributes and storage locations.

- Use inventory management software to attach photos, manuals, and track usage.

- Reorder supplies based on past usage and forecasted needs.

Modern technology enhances tracking. RFID systems enable automatic identification and counting of tagged flashlights, providing real-time visibility and reducing replacement costs. Computer vision systems, such as drone-based inventory scans, count items quickly and accurately, saving labor and preventing stockouts. Asset ID tags with 2D matrix codes and heavy-duty adhesives offer a practical solution, allowing easy scanning with smartphones and supporting GPS tracking.

Maintenance Scheduling for Teams

Coordinating maintenance for multiple flashlights requires structured scheduling. Software platforms like MaintMaster and Accruent Maintenance Connection centralize maintenance information, assign tasks, and provide workload visibility for teams. These systems allow managers to view team workloads, prevent missed tasks, and coordinate across departments.

- Automated scheduling ensures timely maintenance and reduces delays.

- Centralized records improve accountability and communication.

- Mobile access allows teams to update tasks in real time.

- Predictive maintenance features help anticipate failures and optimize resource allocation.

Organizations that adopt these tools report improved efficiency and collaboration. Clear assignment of responsibilities ensures every flashlight receives proper care, reducing downtime and extending equipment life.

Staff Training for Flashlight Care

Proper staff training supports the longevity of industrial flashlights. Teams must understand cleaning routines, battery care, and safe storage practices. Training programs should cover the use of inventory systems, correct labeling, and reporting procedures for damaged equipment.

Well-trained staff reduce the risk of loss, prevent unnecessary repairs, and maintain high productivity. Regular refresher sessions and clear documentation reinforce best practices, ensuring every team member contributes to cost-effective flashlight management.

Organizations that invest in flashlights with proven industrial flashlight durability see fewer repairs and longer equipment life. Teams that follow regular maintenance routines keep their tools reliable and ready. Staff training and efficient inventory management help control costs and boost performance. Proactive troubleshooting addresses issues early, leading to long-term savings.

Choosing the right flashlight and maintaining it well ensures dependable lighting and lower maintenance costs.

FAQ

What makes an industrial flashlight more durable than a standard flashlight?

Manufacturers use robust materials like aluminum alloy and advanced waterproofing. These flashlights withstand impacts, resist corrosion, and perform reliably in harsh environments. High-quality LEDs and reinforced seals further enhance durability.

How often should teams perform maintenance on industrial flashlights?

Teams should inspect and clean flashlights weekly or monthly, depending on usage. Regular maintenance prevents unexpected failures and extends equipment lifespan. Scheduled checks ensure all components function properly.

Can rechargeable flashlights help reduce long-term costs?

Yes. Rechargeable flashlights lower battery replacement expenses and minimize waste. Built-in charging ports and power displays allow users to monitor battery levels, ensuring reliable performance and cost savings over time.

What features should organizations prioritize when selecting industrial flashlights?

Key features include impact resistance, waterproof construction, high-performance LEDs, ergonomic design, and multi-functionality. A numerical power display and emergency power bank capability add extra value for industrial use.

How can staff ensure proper storage of industrial flashlights?

Staff should store flashlights in cool, dry locations away from direct sunlight. Removing batteries during long-term storage prevents leakage. Using labeled racks or cases helps prevent loss and accidental damage.

Post time: Jun-30-2025

fannie@nbtorch.com

fannie@nbtorch.com +0086-0574-28909873

+0086-0574-28909873