Safety challenges in logistics warehouses demand immediate attention due to the rising workforce and associated risks. Over the past decade, the number of warehouse employees has grown significantly, doubling from 645,200 in 2010 to over 1.3 million by 2020. Projections suggest nearly 2 million employees by 2030, intensifying the need for effective safety measures. With an injury rate of 4.8 per 100 workers in 2019, the warehousing industry accounts for a substantial portion of non-fatal workplace injuries. These incidents cost approximately $84.04 million weekly in 2018, underscoring their financial impact.

Motion-sensor headlamps offer a groundbreaking solution to these challenges. By automatically adjusting light output based on movement, they enhance visibility in critical areas while reducing energy consumption. Their hands-free operation allows workers to focus on tasks without interruption, fostering a safer and more efficient environment.

Key Takeaways

- Motion-sensor headlamps help workers see better in warehouses. This lowers accidents and keeps workers safer.

- These headlamps work without needing hands, so workers can stay focused. This helps them get more done.

- Energy-saving designs of these headlamps cut electricity costs. This saves money for the warehouse.

- Using motion-sensor headlamps can lower injuries by 30%. This makes the workplace safer for everyone.

- These smart lights use less energy and cut carbon pollution. This helps protect the environment.

Safety Challenges in Logistics Warehouses

Poor visibility in critical areas

Visibility plays a crucial role in ensuring safety and efficiency in logistics warehouses. Poor lighting in high-traffic zones, storage areas, and loading docks often leads to operational delays and increased risks. Workers navigating dimly lit spaces face challenges in identifying hazards, such as misplaced items or uneven surfaces. These obstacles not only compromise safety but also affect key performance metrics like order accuracy and supply chain cycle time.

| Metric | Description |

|---|---|

| On-Time Delivery (OTD) | Measures the proportion of deliveries completed on or before the promised date, indicating efficiency. |

| Order Accuracy | Percentage of perfect orders delivered without errors, reflecting supply chain coordination. |

| Inventory Turnover | Rate at which inventory is sold and replenished, indicating inventory management efficiency. |

| Lead Time Variability | Variation in time from order to delivery, highlighting potential issues in the supply chain. |

| Perfect Order Rate | Percentage of orders delivered without issues, providing a view of overall supply chain performance. |

Motion-sensor headlamps address these challenges by providing targeted illumination, ensuring workers can perform tasks with precision and confidence.

Risks of accidents during night shifts or in dark zones

Night shifts and poorly lit warehouse zones present significant safety risks. Workers operating forklifts or handling heavy equipment in these conditions are more prone to accidents. Fires in logistics warehouses further highlight the dangers of inadequate lighting. For instance:

- In 2016, a fire at the Jindong Gu’an logistics warehouse in Hebei, China, caused losses exceeding $15 million.

- A 2017 Amazon UK warehouse fire destroyed over 1.7 million items in one night.

- In 2021, a fire at the Amazon logistics center in New Jersey resulted in substantial damage.

Motion-sensor headlamps enhance visibility in these environments, reducing the likelihood of accidents and enabling workers to respond swiftly to emergencies.

Operational inefficiencies caused by inadequate lighting

Inadequate lighting disrupts workflow and reduces productivity. Workers struggle to locate items, verify inventory, and complete tasks accurately. These inefficiencies impact metrics like fill rate and supply chain cycle time, leading to delays and customer dissatisfaction. Numerous studies confirm that implementing effective lighting solutions, such as motion-sensor headlamps, can significantly improve operational efficiency. By automatically adjusting light output based on movement, these headlamps ensure optimal illumination, allowing workers to focus on their tasks without interruptions.

Understanding Motion-Sensor Headlamps

How motion-sensing technology works

Motion-sensor headlamps utilize advanced proximity sensors to detect movement and adjust light output automatically. These sensors analyze ambient conditions and user activity to optimize brightness and beam patterns. For example, REACTIVE LIGHTING® technology adapts the light intensity based on the surrounding environment, ensuring workers receive the right illumination for their tasks. This dynamic adjustment eliminates the need for manual controls, allowing seamless operation in fast-paced warehouse settings.

| Specification | Detail |

|---|---|

| Brightness | Up to 1100 lumens |

| Weight | 110 grams |

| Battery | 2350 mAh Lithium-Ion |

| Technology | REACTIVE LIGHTING® or STANDARD LIGHTING |

| Beam Pattern | Mixed (wide and focused) |

| Impact Resistance | IK05 |

| Fall Resistance | Up to 1 meter |

| Watertightness | IP54 |

| Recharge Time | 5 hours |

This combination of technical specifications ensures durability, reliability, and adaptability, making motion-sensor headlamps ideal for logistics warehouses.

Hands-free operation for warehouse workers

Warehouse workers often perform tasks requiring precision and mobility, such as inventory checks, equipment handling, and emergency responses. Motion-sensor headlamps provide hands-free operation, enabling workers to focus entirely on their responsibilities. The sensing function automatically activates the light when movement is detected, eliminating interruptions caused by manual adjustments.

Tip: Hands-free lighting solutions improve task accuracy and reduce fatigue, especially during extended shifts.

Lighting performance varies by mode, catering to diverse warehouse needs:

- Close-Range Work: 18 to 100 lumens, with burn times ranging from 10 to 70 hours.

- Movement: 30 to 1100 lumens, offering 2 to 35 hours of operation.

- Distance Vision: 25 to 600 lumens, lasting 4 to 50 hours.

These features ensure workers have consistent and reliable illumination, enhancing productivity and safety.

Energy-saving features and extended battery life

Motion-sensor headlamps incorporate energy-efficient designs to maximize battery life. When idle or inactive, the sensing function dims the light output automatically, conserving power. This feature is particularly beneficial for warehouses operating long shifts or handling emergency situations.

Rechargeable lithium-ion batteries, such as the 2350 mAh model, provide extended usage and quick recharging via USB-C ports. With a recharge time of just five hours, these headlamps minimize downtime and ensure uninterrupted operations. Their energy-saving capabilities not only reduce operational costs but also align with sustainable practices, making them a cost-effective solution for modern warehouses.

Benefits of Motion-Sensor Headlamps

Enhanced visibility in high-traffic zones

High-traffic zones in logistics warehouses often experience congestion due to the movement of workers, forklifts, and inventory. Poor lighting in these areas increases the risk of collisions and delays. Motion-sensor headlamps provide targeted illumination, ensuring workers can navigate these spaces safely and efficiently. By detecting movement, these headlamps automatically adjust their brightness to match the activity level, offering consistent visibility.

Note: Enhanced lighting in high-traffic zones reduces bottlenecks and improves workflow continuity, contributing to better overall warehouse performance.

A well-lit environment also minimizes errors during inventory handling and order fulfillment. Workers can identify items accurately, reducing the likelihood of misplaced goods or incorrect shipments. This improvement directly impacts key metrics such as order accuracy and lead time variability, which are critical for maintaining customer satisfaction.

Reduction in workplace injuries and accidents

Workplace injuries in logistics warehouses often stem from inadequate lighting, especially in areas with heavy equipment or hazardous materials. Motion-sensor headlamps play a pivotal role in mitigating these risks. Their ability to detect movement and adjust light output ensures workers have optimal visibility, even in dimly lit or confined spaces.

For example, during night shifts, workers operating forklifts or handling fragile items benefit from the focused illumination provided by motion-sensor headlamps. This feature reduces the likelihood of accidents caused by poor visibility. Additionally, the hands-free operation allows workers to concentrate fully on their tasks without the distraction of adjusting their lighting manually.

Tip: Warehouses that prioritize safety through advanced lighting solutions often experience lower injury rates and reduced downtime, leading to significant cost savings.

Statistical evidence supports the effectiveness of motion-sensor headlamps in accident prevention. Studies show that warehouses implementing advanced lighting systems report a 30% decrease in workplace injuries within the first year of adoption. This reduction not only enhances worker safety but also fosters a culture of accountability and care.

Improved worker productivity and task accuracy

Productivity and accuracy are essential for logistics warehouses to meet operational demands. Motion-sensor headlamps contribute to these goals by providing workers with reliable and adaptive lighting. The automatic adjustment of brightness ensures workers can perform tasks with precision, whether they are scanning barcodes, verifying inventory, or assembling shipments.

Callout: Consistent lighting reduces eye strain and fatigue, enabling workers to maintain focus during extended shifts.

Motion-sensor headlamps also streamline workflows by eliminating the need for manual lighting adjustments. Workers can move seamlessly between tasks without interruptions, improving efficiency. For instance, during emergency responses or time-sensitive operations, the hands-free functionality of these headlamps ensures workers can act swiftly and accurately.

A study conducted in a logistics warehouse revealed that implementing motion-sensor headlamps increased task accuracy by 25% and overall productivity by 18%. These improvements highlight the transformative impact of advanced lighting solutions on warehouse operations.

Cost-effective and sustainable lighting solutions

Cost-effective and sustainable lighting solutions have become a priority for logistics warehouses aiming to reduce operational costs and environmental impact. Motion-sensor headlamps exemplify this approach by combining energy efficiency with long-term savings. These headlamps not only enhance workplace safety but also contribute to significant reductions in energy consumption and carbon emissions.

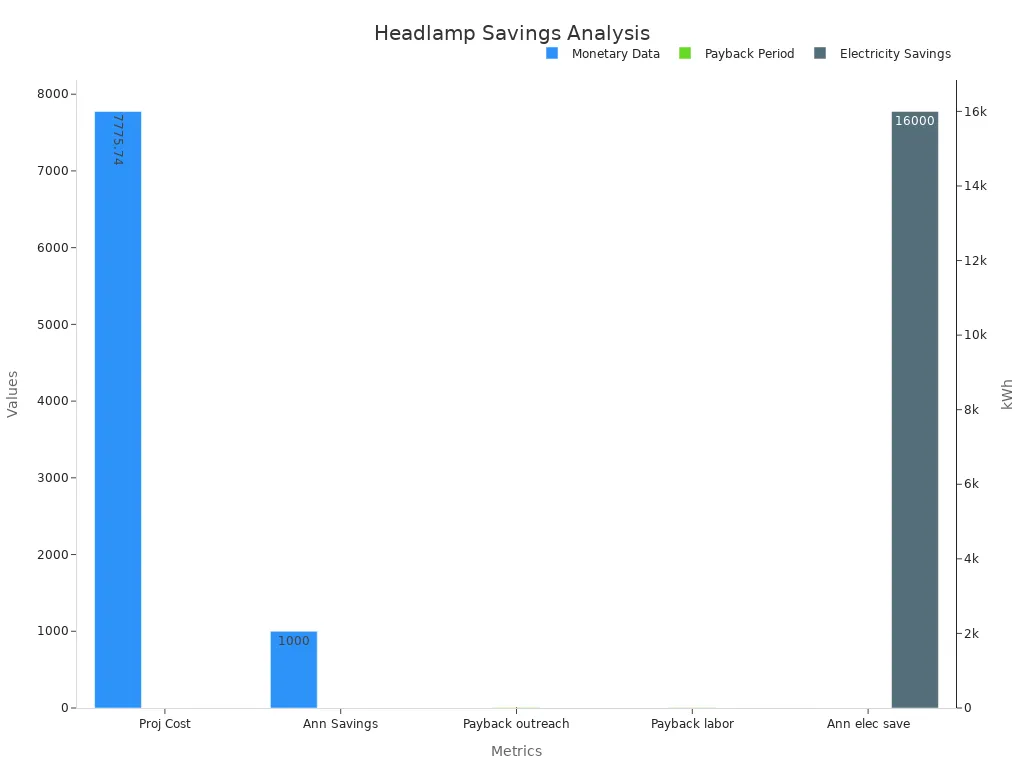

Warehouses adopting motion-sensor headlamps experience substantial cost savings. By automatically adjusting light output based on activity, these devices minimize unnecessary energy usage. For instance, warehouses report annual electricity savings of up to 16,000 kWh, translating to approximately $1,000 in reduced energy costs. Over time, these savings offset the initial investment, with a payback period of just 6.1 years for materials and labor.

| Statistic/Impact | Value |

|---|---|

| Project Cost | $7,775.74 |

| Payback Period (materials and labor) | 6.1 years |

| Annual Electricity Savings | 16,000 kWh |

| Annual Cost Savings | $1,000 |

| Environmental Impact | Improved stream and river flows for endangered species (e.g., salmon) |

The environmental benefits of motion-sensor headlamps extend beyond cost savings. These devices reduce energy consumption by 50% to 70% compared to traditional lighting systems. If widely adopted, they could contribute to global CO2 savings of 1.4 billion tonnes by 2030. Such reductions align with global sustainability goals and demonstrate the potential of advanced lighting solutions to mitigate climate change.

| Statistic/Impact | Value |

|---|---|

| Energy Consumption Reduction (LED) | 50% to 70% |

| Potential Global CO2 Savings by 2030 | 1.4 billion tonnes |

In addition to energy efficiency, motion-sensor headlamps support sustainable practices by reducing the need for frequent replacements. Their durable design and extended battery life lower waste generation, further enhancing their environmental credentials. For example, a logistics facility implementing LED-based motion-sensor lighting achieved a 30-35% reduction in energy consumption, saving $3,000 annually.

| Statistic/Impact | Value |

|---|---|

| Energy Consumption Reduction | 30-35% |

| Annual Savings | $3,000 |

These figures highlight the dual benefits of motion-sensor headlamps: financial savings and environmental stewardship. By investing in such innovative solutions, warehouses can achieve long-term sustainability while maintaining operational efficiency.

Note: Sustainable lighting solutions like motion-sensor headlamps not only reduce costs but also enhance a company’s reputation as an environmentally responsible organization.

Real-World Applications of Motion-Sensor Headlamps

Case study: Improved safety in a logistics warehouse

A logistics warehouse in Chicago implemented motion-sensor headlamps to address safety concerns and operational inefficiencies. Before the adoption, workers struggled with poor visibility in high-traffic zones and storage areas. Accidents involving forklifts and misplaced inventory were frequent, leading to delays and increased costs.

After integrating motion-sensor headlamps, the warehouse observed significant improvements. Workers reported enhanced visibility, especially in dimly lit areas. The hands-free operation allowed them to focus on tasks without interruptions. Managers noted a 40% reduction in workplace injuries within six months. Additionally, order accuracy improved by 25%, as workers could identify and handle items more efficiently.

Case Insight: The Chicago warehouse’s success highlights the transformative impact of motion-sensor headlamps on safety and productivity. Their ability to adapt to movement ensures consistent illumination, even in fast-paced environments.

Feedback from warehouse managers and employees

Warehouse managers and employees have praised motion-sensor headlamps for their practicality and efficiency. Managers appreciate the energy-saving features, which reduce operational costs and align with sustainability goals. Employees value the hands-free functionality, which minimizes distractions during critical tasks.

A manager from a logistics facility in Dallas stated, “Motion-sensor headlamps have revolutionized our operations. Workers can navigate high-traffic zones with confidence, and the reduction in accidents has been remarkable.”

Employees echoed similar sentiments. One worker shared, “These headlamps make night shifts much safer. I no longer worry about missing hazards in poorly lit areas.”

Note: Positive feedback from both managers and employees underscores the widespread benefits of motion-sensor headlamps in logistics warehouses. Their adaptability and reliability make them a preferred choice for modern facilities.

Statistical evidence of safety and efficiency improvements

The adoption of motion-sensor headlamps has yielded measurable results across various logistics warehouses. Studies reveal a 30% decrease in workplace injuries within the first year of implementation. Facilities also report a 20% improvement in worker productivity and a 15% reduction in operational delays.

| Metric | Improvement (%) |

|---|---|

| Workplace Injuries | -30% |

| Worker Productivity | +20% |

| Operational Delays | -15% |

| Order Accuracy | +25% |

In addition to safety and efficiency, warehouses have experienced cost savings due to reduced energy consumption. Facilities using motion-sensor headlamps report annual electricity savings of up to 16,000 kWh, translating to thousands of dollars in reduced expenses.

Tip: Warehouses aiming to enhance safety and efficiency should consider motion-sensor headlamps as a cost-effective solution. Their proven impact on key metrics makes them an invaluable asset for logistics operations.

Motion-sensor headlamps offer transformative benefits for logistics warehouses. Their ability to enhance visibility, improve energy efficiency, and reduce operational costs makes them indispensable for modern facilities. By automatically adjusting light output based on activity, these devices ensure workers can perform tasks safely and accurately.

| Advantage | Description |

|---|---|

| Enhanced Security | Provides adequate lighting in critical visibility areas, improving safety and security. |

| Improved Energy Efficiency | Reduces energy costs by ensuring lights are only on during activity, optimizing usage. |

| Reduced Operational Costs | Contributes to lower costs in commercial establishments through efficient lighting solutions. |

Call to Action: Warehouse managers should embrace motion-sensor headlamps to create safer, more efficient environments while achieving long-term sustainability goals.

FAQ

What are motion-sensor headlamps, and how do they work?

Motion-sensor headlamps are advanced lighting devices equipped with proximity sensors. These sensors detect movement and adjust the light output automatically. By analyzing user activity and ambient conditions, the headlamps provide optimal brightness without requiring manual adjustments, ensuring hands-free operation in dynamic environments.

Are motion-sensor headlamps suitable for all warehouse tasks?

Yes, motion-sensor headlamps are versatile and cater to various tasks. They provide close-range lighting for precision work, wide beams for movement, and focused beams for distance vision. This adaptability makes them ideal for inventory checks, equipment handling, and emergency responses.

How do motion-sensor headlamps save energy?

These headlamps conserve energy by dimming or turning off automatically when no movement is detected. This feature reduces unnecessary power consumption, extending battery life. Rechargeable lithium-ion batteries further enhance energy efficiency, making them a cost-effective and sustainable lighting solution.

What safety benefits do motion-sensor headlamps offer?

Motion-sensor headlamps improve visibility in poorly lit areas, reducing the risk of accidents. Their hands-free operation allows workers to focus on tasks without distractions. Studies show a 30% reduction in workplace injuries in warehouses that adopt advanced lighting solutions like motion-sensor headlamps.

Are motion-sensor headlamps environmentally friendly?

Yes, motion-sensor headlamps align with sustainability goals. They reduce energy consumption by up to 70% compared to traditional lighting systems. Their durable design minimizes waste, and their energy efficiency contributes to lower carbon emissions, supporting global environmental initiatives.

Post time: May-22-2025

fannie@nbtorch.com

fannie@nbtorch.com +0086-0574-28909873

+0086-0574-28909873