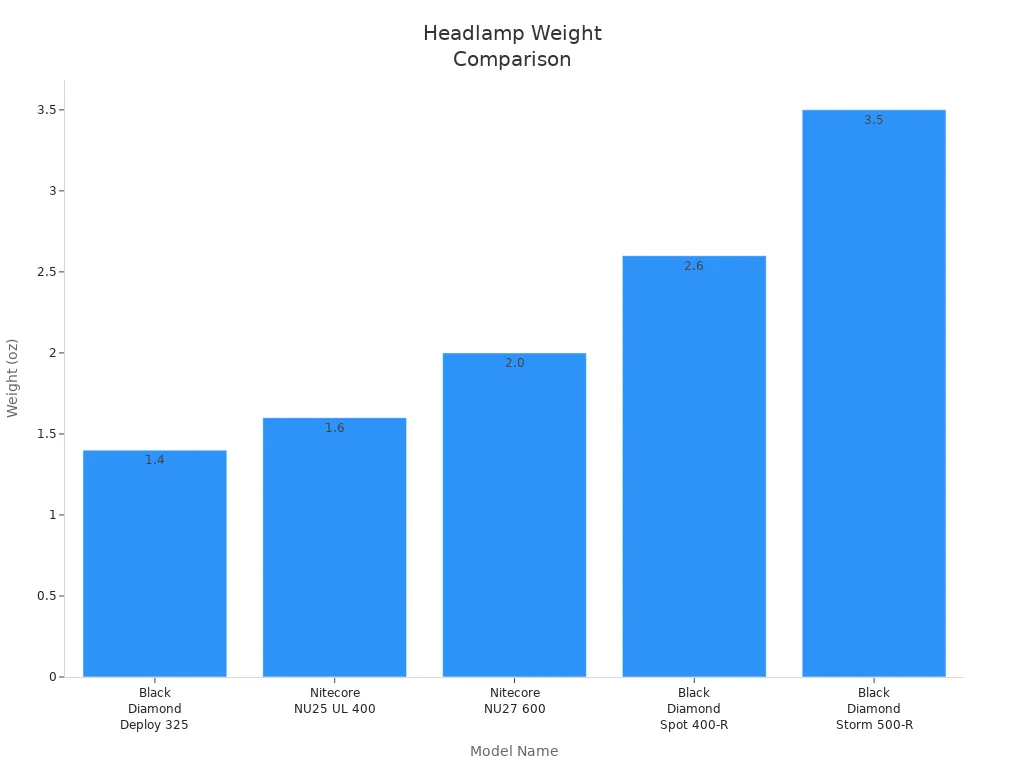

Outdoor enthusiasts often choose equipment that offers the best balance between performance and weight. Ultra-light COB headlamp design achieves a 35% weight reduction by combining innovative materials, compact electronics, and COB LED integration. The following table shows how leading ultralight models compare to traditional headlamps:

| Headlamp Type | Model Name | Weight (oz) | Weight Reduction Compared to Traditional (oz) |

|---|---|---|---|

| Ultralight COB Headlamp | Black Diamond Deploy 325 | 1.4 | 1.2 (vs BD Spot 400-R at 2.6 oz) |

| Ultralight COB Headlamp | Nitecore NU25 UL 400 | 1.6 | 1.0 (vs BD Spot 400-R at 2.6 oz) |

| Ultralight COB Headlamp | Nitecore NU27 600 | 2.0 | 0.6 (vs BD Spot 400-R at 2.6 oz) |

| Traditional Headlamp | Black Diamond Spot 400-R | 2.6 | N/A |

| Traditional Headlamp | Black Diamond Storm 500-R | 3.5 | N/A |

A 35% reduction in weight transforms the hiking experience. Hikers move faster and more comfortably with less bulk and fatigue. Hiking brands that embrace this technology gain a clear edge in the outdoor gear market.

Key Takeaways

- Ultra-light COB headlamps reduce weight by about 35%, making hiking easier and more comfortable.

- COB LED technology combines multiple LED chips into a small, efficient module that produces bright, even light with less power.

- Using lightweight materials like ABS and polypropylene helps lower headlamp weight while keeping durability and eco-friendliness.

- Smart power management and compact battery designs extend battery life and improve reliability without adding bulk.

- Hiking brands that adopt ultra-light COB headlamps gain a competitive edge by offering lighter, high-performance gear that appeals to outdoor enthusiasts.

Ultra-Light COB Headlamp Technology Explained

What is COB (Chip-on-Board) LED?

COB (Chip-on-Board) LED technology represents a significant advancement in lighting. Manufacturers mount multiple bare LED chips directly onto an ultra-thin printed circuit board, usually between 0.4 and 1.2 millimeters thick. This process eliminates the need for individual LED packaging and reduces the number of components required. The result is a compact, lightweight, and highly efficient lighting module.

Note: COB LEDs use only two electrical contacts to energize all the chips, which simplifies the design and reduces potential points of failure. This direct bonding method also improves heat transfer, making the system more reliable and durable.

The structure of COB LEDs supports the development of ultra-light COB headlamp models. By removing excess brackets and soldering steps, designers achieve a thinner and lighter product that remains robust and easy to install.

Advantages of COB LEDs in Headlamp Design

COB LEDs offer several advantages that make them ideal for headlamp applications:

- Multiple LED chips bonded directly to the substrate create a higher light output density and more effective use of space.

- The compact design allows for a broader beam angle, providing even illumination over a larger area.

- Fewer components mean greater efficiency and a longer lifespan, as there are fewer points of failure.

- Superior heat dissipation ensures stable performance and extends the operational life of the headlamp.

- The uniform light output eliminates the spotty or clustered effect seen in other LED types, delivering smooth and consistent illumination.

- Integrated optics, such as lenses and reflectors, focus and direct light precisely, which is essential for outdoor activities.

Laboratory tests show that COB LEDs achieve luminous efficiencies ranging from 80 to 250 lumens per watt. This efficiency surpasses traditional LED technologies, resulting in brighter light with less power consumption. In battery-powered scenarios, such as hiking, users benefit from longer runtimes and more reliable performance. The combination of high brightness, energy efficiency, and durability positions the ultra-light COB headlamp as a top choice for outdoor enthusiasts.

Design Innovations Driving Weight Reduction

Advanced Material Selection for Ultra-Light COB Headlamp

Material choice plays a critical role in reducing the weight of modern headlamps. Manufacturers now favor advanced lightweight materials such as ABS (Acrylonitrile Butadiene Styrene) and PP (Polypropylene) for their excellent strength-to-weight ratios. ABS weighs only about one-seventh as much as steel, which significantly lowers the overall mass of the headlamp. These materials also offer chemical stability and corrosion resistance, which extends product life and reduces the need for frequent replacements.

ABS and PP are both recyclable and non-toxic, making them environmentally friendly options. Many brands incorporate recycled plastics and composite materials into headlamp shells, which helps conserve resources and minimize pollution. Certifications like CE and ROHS confirm that these materials meet strict environmental safety standards. Eco-friendly packaging, such as recyclable paper, further reduces the environmental impact of ultra-light COB headlamp production.

Streamlined Housing and Compact Form Factor

Designers achieve significant weight reduction by rethinking the headlamp’s housing and form factor. Integrating multiple LED chips into a single COB module reduces the overall thickness by up to 60%. Thinner printed circuit boards, often between 0.4 and 1.2 millimeters, further decrease module weight. Eliminating bulky brackets can cut the module’s weight by as much as 70%. Flexible COB variants allow for bending and compactness, which supports more efficient and lightweight headlamp housings.

Several engineering techniques contribute to these streamlined designs:

- Advanced 3D engineering and molding create hollowed shapes that reduce weight while maintaining structural integrity.

- Flexible plastic tongues with gear-like indexers hold the lamp at any angle, removing the need for extra parts or springs.

- Compact assembly of electronics and optics minimizes the overall footprint.

- Hollowed shapes serve dual purposes, such as reducing weight and enabling features like hanging the lamp.

- Small, efficient clips on the main body provide easy battery access without bulky mechanisms.

- Careful balancing of thermal management components ensures durability within strict weight and space constraints.

These features not only reduce the weight of the headlamp but also lower installation and transportation costs for brands.

Efficient Power Management and Battery Integration

Innovations in power management and battery integration have enabled lighter and more efficient headlamp designs. Smart Power Control systems optimize battery life by managing smooth transitions between light modes, which reduces unnecessary power consumption. Flex-Power technology allows users to choose between rechargeable or disposable batteries, offering flexibility and the option to use lighter battery types.

Smart Temperature Control circuitry actively regulates light output and temperature. This preserves battery life and ensures safe operation, which supports efficient power management. Advanced COB LED technology integrates more LED chips into panels, delivering strong, uniform beams with efficient power use. This allows for smaller, lighter designs without sacrificing brightness or battery longevity.

Premium materials such as aluminum with high strength-to-weight ratios and anodized finishes ensure durability while keeping the headlamp lightweight. Compact electronics, including tightly packed LED chips on a silicon carbide base, enable efficient heat transmission to heat sinks. This prevents overheating and extends the lifespan of the headlamp. The simplified construction of COB LEDs, with fewer contacts and circuits, results in lower failure rates and enhanced reliability. Many ultra-light COB headlamp models now achieve a rated lifetime of around 50,000 hours under typical usage conditions.

Tip: Efficient power management and compact battery integration not only reduce weight but also improve user convenience and product reliability.

Quantifying the 35% Weight Reduction in Ultra-Light COB Headlamp

Before-and-After Weight Comparisons

Hiking brands have made significant progress in reducing the weight of headlamps. The shift from traditional LED modules to COB technology has enabled designers to create lighter products without sacrificing performance. The following table highlights the weight differences between conventional headlamps and their ultra-light COB counterparts:

| Model Type | Example Model | Weight (oz) | Weight Reduction (%) |

|---|---|---|---|

| Traditional Headlamp | Black Diamond Spot 400-R | 2.6 | 0 |

| Ultra-Light COB Headlamp | Nitecore NU25 UL 400 | 1.6 | 38 |

| Ultra-Light COB Headlamp | Black Diamond Deploy 325 | 1.4 | 46 |

These numbers show a clear trend. Ultra-light COB headlamp models consistently weigh less than their traditional counterparts. For example, the Nitecore NU25 UL 400 achieves a 38% reduction in weight compared to the Black Diamond Spot 400-R. The Black Diamond Deploy 325 goes even further, reducing weight by 46%. This reduction translates to less strain on hikers and more efficient packing for outdoor adventures.

Note: Even a small decrease in gear weight can make a big difference during long hikes. Lighter headlamps help users move faster and conserve energy.

Testing and Validation Methods

Manufacturers use rigorous testing and validation methods to confirm weight reduction claims. These processes ensure that the ultra-light COB headlamp meets both performance and durability standards. The following steps outline the typical validation workflow:

- Precision Weighing: Engineers use calibrated digital scales to measure the headlamp’s weight before and after design changes. They record each measurement under controlled conditions to ensure accuracy.

- Component Analysis: Teams disassemble the headlamp to weigh individual parts. This analysis identifies which components contribute most to overall weight and guides further optimization.

- Field Testing: Testers evaluate the headlamp in real-world hiking scenarios. They assess comfort, balance, and ease of use while wearing the device for extended periods.

- Durability Assessment: Quality control teams subject the headlamp to drop tests, vibration tests, and temperature cycling. These tests confirm that weight reduction does not compromise structural integrity.

- Battery Runtime Verification: Technicians measure battery life under various lighting modes. They ensure that lighter designs still deliver reliable performance.

Manufacturers document all results and compare them to industry benchmarks. This data-driven approach guarantees that each ultra-light COB headlamp delivers on its promise of reduced weight and high functionality.

Tip: Brands that invest in thorough testing build trust with customers and set themselves apart in the competitive outdoor gear market.

Impact of Ultra-Light COB Headlamp on Hiking Brands and Users

Competitive Advantages for Hiking Brands

Hiking brands that adopt ultra-light COB headlamp technology gain a clear edge in the outdoor gear market. They offer products that meet the growing demand for lightweight, high-performance equipment. Brands can highlight the 35% weight reduction as a key selling point. This feature attracts both experienced hikers and newcomers who value comfort and efficiency.

Manufacturers benefit from streamlined production processes. The integration of COB LEDs reduces the number of components, which lowers assembly costs and shortens lead times. Brands can pass these savings on to customers or reinvest in research and development. Certifications such as CE and RoHS enhance credibility and open doors to global markets.

A table below summarizes the main competitive advantages:

| Advantage | Description |

|---|---|

| Weight Reduction | 35% lighter than traditional headlamps |

| Production Efficiency | Fewer components, faster assembly |

| Market Appeal | Attracts weight-conscious outdoor enthusiasts |

| Certification | Meets CE, RoHS, ISO standards |

Brands that innovate with ultra-light COB headlamp designs position themselves as leaders in outdoor technology.

Enhanced User Experience for Hikers

Hikers experience immediate benefits when using ultra-light COB headlamps. The reduced weight lessens fatigue during long treks. Users enjoy greater freedom of movement and improved comfort, especially on multi-day hikes. The compact form factor allows for easy packing and quick access.

COB LED technology delivers uniform illumination. Hikers see trails and obstacles more clearly, which increases safety during nighttime activities. Rechargeable battery options provide cost savings and convenience. Many models feature intuitive controls and adjustable angles, making them suitable for a variety of outdoor scenarios.

- Users report longer battery life and reliable performance in challenging conditions.

- The headlamp’s durability ensures it withstands drops, rain, and temperature changes.

- Eco-friendly materials appeal to environmentally conscious consumers.

Hikers who choose ultra-light COB headlamps gain a dependable tool that enhances every outdoor adventure.

Implementation Strategies for Ultra-Light COB Headlamp Design

Key Design Considerations for Brands

Brands aiming to lead in headlamp innovation must prioritize several critical design factors. The following table summarizes the most important considerations and their impact on product performance:

| Design Consideration | Explanation | Importance for Ultra-Light COB Headlamps |

|---|---|---|

| Lumen Output Accuracy | Genuine lumen ratings verified by independent reviews and certifications prevent misleading claims. | Ensures realistic brightness expectations and compliance with safety norms. |

| Thermal Management | Cooling methods include fan-cooled (active), passive heatsinks, and liquid cooling systems. | Critical to dissipate heat from compact, heat-sensitive COB LEDs to maintain brightness and longevity. |

| Legal Compliance | Adhering to regulations on brightness and beam alignment. | Avoids legal issues and ensures safety for all road users. |

| Optical Placement & Beam Technology | Proper positioning and choice between single-beam or dual-beam lenses affect light distribution. | Optimizes effective illumination and reduces glare. |

| Driver Circuit Stability & CANBUS Compatibility | Stable power supply and vehicle communication compatibility. | Maintains consistent performance and integration with vehicle electronics. |

| Color Temperature Selection | Options range from warm yellow (3000K) to cool white (6000-6500K), affecting visibility and comfort. | Tailors light output to driving conditions and user preference. |

Leading hiking brands also focus on weight, battery life, and durability. They use lightweight plastics and aluminum alloys for the shell, and select lithium-ion rechargeable batteries for reduced weight. Multiple light modes help balance brightness and runtime. Waterproof and impact-resistant materials, such as ABS and silicone, ensure the headlamp withstands harsh outdoor conditions. Features like adjustable tilt and motion sensors improve usability and comfort.

Tip: Brands should balance weight reduction with battery life and ruggedness to meet the needs of outdoor enthusiasts.

Sourcing and Manufacturing Recommendations

Sourcing high-quality, lightweight materials is essential for reliable headlamp production. The table below outlines the most effective materials and their advantages:

| Material Type | Application in Headlamp Manufacturing | Key Advantages | Cost Level |

|---|---|---|---|

| Premium LED Chips | Core light source for brightness and efficiency | High brightness, long lifespan | High |

| High-grade PCBs | Base for LED mounting and heat dissipation | Excellent heat management, durability, flexibility | Low-High |

| Silicone Encapsulation | Protective coating for environmental resistance | Superior moisture, dust, UV protection | Medium |

| Polycarbonate Lenses/Housings | Protective cover with optical clarity and impact resistance | Strong, clear, moldable, impact resistant | Medium |

Manufacturers like Maytown demonstrate best practices by sourcing from trusted suppliers and maintaining strict quality control through ISO9001 and RoHS certifications. In-house production capabilities, such as CNC machining and advanced mold design, enable precise manufacturing of lightweight components. Brands benefit from robust supply chains that support both low and high-volume orders, ensuring consistent quality and timely delivery.

Manufacturing processes for COB headlamps involve multiple steps, including substrate preparation, chip mounting, and protective layering. While these steps add complexity, they allow for lower initial manufacturing costs per lumen and support intense light output. Brands should address challenges such as advanced thermal management and voltage sensitivity by investing in quality drivers and standardized interfaces.

Note: Regular supplier evaluation and volume ordering help optimize both cost and quality, supporting long-term success in the competitive outdoor lighting market.

Outdoor brands see clear advantages when they adopt lighter headlamp designs. Users enjoy less fatigue, longer battery life, and reliable performance on every adventure.

- Brands gain a competitive edge with faster production and greater market appeal.

- Eco-friendly materials and certifications support global sales.

Forward-thinking brands should embrace these innovations to lead the outdoor lighting market and meet the needs of modern hikers.

FAQ

What makes COB headlamps lighter than traditional models?

COB headlamps use integrated LED chips and advanced plastics. This design reduces the number of components and lowers the overall weight. Brands achieve a compact, efficient product without sacrificing brightness or durability.

How long does the battery last in an ultra-light COB headlamp?

Battery life depends on the model and light mode. Most ultra-light COB headlamps provide 5–40 hours of runtime. Efficient power management and rechargeable batteries extend usage for multi-day hikes.

Are ultra-light COB headlamps durable for outdoor use?

Manufacturers use impact-resistant materials and waterproof designs. These headlamps withstand drops, rain, and temperature changes. Outdoor enthusiasts rely on them for reliable performance in challenging environments.

Can users recharge ultra-light COB headlamps easily?

Most models feature built-in USB charging ports. Users can recharge the headlamp with power banks, laptops, or wall adapters. This feature offers convenience during extended outdoor trips.

Do ultra-light COB headlamps meet safety and environmental standards?

Leading brands certify their headlamps with CE, RoHS, and ISO standards. These certifications ensure product safety, environmental responsibility, and global market acceptance.

Post time: Aug-13-2025

fannie@nbtorch.com

fannie@nbtorch.com +0086-0574-28909873

+0086-0574-28909873