Sensor headlamps significantly enhance worker visibility, reducing hands-on tasks in hazardous environments. These essential devices improve overall operational efficiency and incident prevention within the oil and gas industry. Explosion-proof sensor headlamps are crucial for mitigating the unique risks inherent in this sector. They provide critical illumination and facilitate hands-free operation, directly protecting personnel and assets.

Key Takeaways

- Sensor headlamps make work safer in oil and gas jobs. They help workers see better and keep their hands free.

- These headlamps are ‘explosion-proof.’ This means they will not cause fires or explosions around dangerous gases.

- They have smart lights that change how bright they are. This helps workers see clearly without blinding others.

- Sensor headlamps are strong and last a long time. They work well even in bad weather or tough places.

- Using these headlamps helps companies follow safety rules. They also make workers feel more confident and work better.

Unique Safety Challenges in Oil & Gas Environments

The oil and gas industry presents a demanding work environment. Workers face numerous hazards daily. These challenges necessitate specialized safety equipment and rigorous protocols.

Low-Light and Confined Spaces

Many operations in oil and gas facilities occur in areas with poor visibility. Workers often navigate dark pipelines, storage tanks, or underground structures. These confined spaces restrict movement and limit natural light. Poor lighting increases the risk of accidents. Workers can easily miss obstacles or misjudge distances. This environment demands reliable and effective illumination.

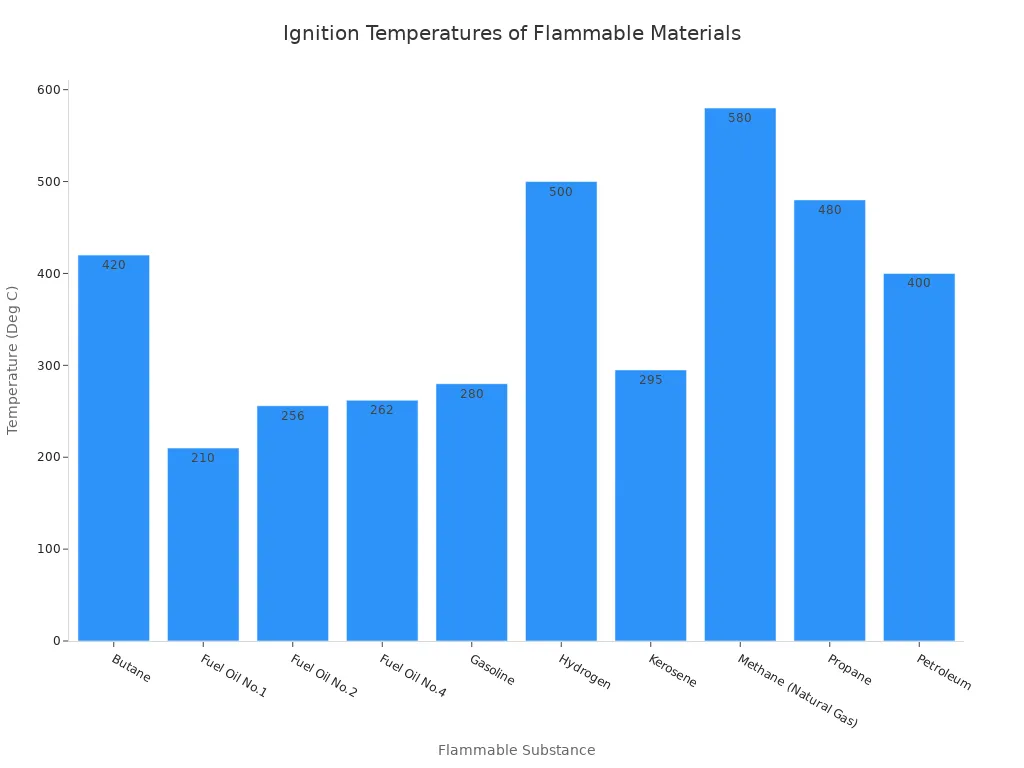

Presence of Flammable Materials

Oil and gas operations inherently involve highly flammable substances. The presence of these materials creates a constant risk of fire or explosion. Even a small spark can ignite vapors or gases. Understanding the ignition temperatures of these substances is crucial for safety.

| Flammable Substance | Temp (Deg C) | Temp (Deg F) |

|---|---|---|

| Butane | 420 | 788 |

| Fuel Oil No.1 | 210 | 410 |

| Fuel Oil No.2 | 256 | 494 |

| Fuel Oil No.4 | 262 | 505 |

| Gasoline | 280 | 536 |

| Hydrogen | 500 | 932 |

| Kerosene | 295 | 563 |

| Methane (Natural Gas) | 580 | 1076 |

| Propane | 480 | 842 |

| Petroleum | 400 | 752 |

Workers must use equipment designed to prevent ignition in these hazardous zones.

Complex Machinery and Moving Parts

Oil and gas facilities house extensive and powerful machinery. These machines often feature numerous moving parts. They pose significant crush, pinch, and entanglement hazards. Workers frequently interact with equipment such as:

- Winches

- Booms

- Drawworks

- Pumps

- Compressors

- Belt wheels

- Catheads

- Hoist blocks

- Cranes

- Drill equipment

These components move with immense force. They require constant vigilance and precise actions from personnel. Any distraction or misstep can lead to severe injury.

Harsh Weather Conditions and Their Impact

Oil and gas operations often occur in remote and extreme environments. Workers face severe weather conditions. These conditions significantly increase operational risks and threaten worker safety. Unpredictable weather patterns make tasks more challenging and dangerous.

Various weather conditions pose distinct threats to personnel.

| Weather Condition | Impact on Worker Safety |

|---|---|

| Heavy Rainfall | Increased risk of landslides and unstable pits; flooding |

| High Winds | Reduced visibility due to stirred-up dust; affected air quality |

| Extreme Heat | Risk of heatstroke, requiring strict heat management protocols |

| Tumultuous Seas (Offshore) | Operations become risky, potential for worker evacuation, equipment damage leading to hazardous situations like oil spills |

| These elements directly affect visibility, equipment stability, and worker health. They demand constant vigilance and robust safety measures. |

Climate change intensifies extreme weather events. These events become more frequent and severe. This leads to unpredictable and rapidly changing weather patterns. Such patterns are significant risk factors in the oil and gas industries. Climate change also heightens other risks. These include increased fire hazards and flooding. They affect both operations and surrounding communities.

Workers must perform critical tasks despite these environmental challenges. They need reliable tools to maintain safety and efficiency. Harsh weather conditions complicate communication and emergency response. They also increase the likelihood of equipment failure. This environment necessitates advanced safety solutions.

How Explosion-Proof Sensor Headlamps Address These Challenges

Explosion-proof sensor headlamps offer critical solutions to the inherent dangers of oil and gas environments. These advanced devices directly enhance worker safety and operational efficiency. They provide specialized features that mitigate risks associated with low-light conditions, flammable materials, and complex machinery.

Hands-Free Operation for Enhanced Safety

Hands-free operation is a cornerstone of safety in hazardous industrial settings. Workers often require both hands to perform intricate tasks, operate machinery, or navigate challenging terrain. Traditional handheld lights occupy one hand, reducing a worker’s ability to maintain balance or perform critical functions. Sensor headlamps eliminate this problem by providing continuous illumination directly where the worker looks. This allows personnel to focus entirely on their tasks.

Headlamps ensure your work area remains consistently lit as you move around equipment. This consistent lighting helps prevent tools from being dropped into machinery. It also reduces the risk of electrical shorts when working on wiring in dim conditions.

By keeping both hands free, workers can securely hold tools, climb ladders, or operate controls with greater stability and precision. This significantly reduces the risk of accidents, such as falls or dropped objects, which can cause serious injury or equipment damage.

Adaptive Lighting Technology for Optimal Visibility

Adaptive lighting technology in explosion-proof sensor headlamps provides optimal visibility by adjusting light output to specific environmental conditions. These systems do not simply turn on or off; they intelligently respond to the surrounding light and the worker’s activity. Most adaptive headlamp systems incorporate a self-leveling mechanism with an additional level sensor. This sensor detects if the worker’s head tilts forward or backward. Electric servomotors react to the sensor’s input, keeping the light beam aimed correctly. This prevents the beam from temporarily pointing upwards and dazzling others. Adaptive headlamps also adjust based on movement, speed, and elevation to ensure continuous proper illumination.

Modern adaptive lighting offers various modes to suit different operational needs:

- Town light: This mode activates up to 55 km/h. It features a horizontal cut-off line to minimize glare and provides wide illumination for pedestrian detection.

- Country light: Active between 55 and 100 km/h, this mode resembles a conventional low beam. It uses a VarioX® module for asymmetric light distribution to avoid glare, with a raised cut-off line for better left-edge illumination and range.

- Highway light: This mode activates above 100 km/h. It adapts light distribution range for high curve radii at high speeds.

- Adverse weather light: This mode creates wider light dispersion for improved visibility in rain, fog, or snow. It also reduces far-field illumination to minimize reflective glare for the driver.

An Adaptive Frontlighting System (AFS) headlamp utilizes a VarioX® projection module. A rotating cylinder positions itself between the light source and lens. This cylinder has varying contours and can rotate around its longitudinal axis. A stepper motor drives this rotation, adjusting its position within milliseconds to achieve different light distributions. The system processes data from various in-vehicle sources. It calculates and implements individual light functions, adapting to vehicle speed, road type, and weather conditions. This intelligent adjustment ensures workers always have the best possible illumination without causing glare or wasting battery life.

Intrinsically Safe Design for Hazardous Zones

The presence of flammable materials in oil and gas environments demands equipment with an intrinsically safe design. This design prevents the headlamp from generating sparks or heat capable of igniting explosive gases or vapors. For hazardous locations in the oil and gas industry, lighting equipment like headlamps must be certified for intrinsic safety. Specifically, Class I Division 1 headlamps are engineered for these environments. These certifications are defined by NEC standards in North America, where:

- Class I indicates hazardous gases or vapors (e.g., methane, propane).

- Division 1 signifies that explosive concentrations exist during normal operations.

Additionally, Nightstick’s Class I Div 1 models are rigorously tested and compliant with ATEX, IECEx, and cETLus standards. Choosing a certified headlamp ensures:

- Compliance with OSHA and NFPA standards

- Reduced ignition risk from heat or sparks

- Long-term reliability in demanding environments

For international operations, headlamps with dual certifications (ATEX / IECEx) are recommended. For headlamps in hazardous zones within the oil and gas industry, ATEX, IECEx, and UL Class I, Division 1 certifications are crucial. ATEX, derived from the European Union’s directives, is the standard for equipment in explosive atmospheres across Europe. It classifies equipment into zones based on explosion likelihood. IECEx, an international system, harmonizes safety standards globally for equipment in explosive environments. Multinational operations like oil rigs often use IECEx certified equipment. UL certifications, particularly UL Class I, Division 1 and 2, are dominant in North America for environments with flammable gases, vapors, or liquids. These certifications ensure that equipment, including explosion-proof sensor headlamps, is engineered to eliminate ignition sources and withstand hazardous conditions. This is a non-negotiable requirement in the oil and gas sector due to the presence of volatile hydrocarbons.

Specific intrinsic safety certifications required for headlamps in hazardous zones within the oil and gas industry include:

- UL Certification

- ATEX (Essential health and safety requirements)

- IECEx (Safety standard in hazardous areas)

These certifications provide assurance that the headlamps will not become an ignition source, protecting workers and preventing catastrophic incidents.

Enhanced Durability and Reliability in Extreme Conditions

Oil and gas operations expose equipment to some of the planet’s most challenging environments. Sensor headlamps must withstand these conditions to remain effective safety tools. Manufacturers design these devices with enhanced durability and reliability as core principles. They ensure the headlamps function flawlessly in extreme temperatures, corrosive atmospheres, and high-impact situations.

The construction of these headlamps incorporates advanced materials. Polycarbonate and tempered glass provide exceptional resistance against impacts, extreme temperatures, and harsh chemicals. Special coatings protect components from corrosion and wear, extending the headlamp’s lifespan. For environments with radiation exposure, materials like Gallium Nitride (GaN) and Silicon Carbide (SiC) offer superior resilience.

Robust construction is a hallmark of these specialized headlamps. Explosion-proof lights prevent the ignition of flammable gases or particles. They feature specialized sealing and precise temperature control mechanisms. This design ensures the headlamp itself does not become an ignition source. In offshore environments, marine-grade, low-copper aluminum or stainless steel mounting brackets combat severe corrosion. Anodized aluminum alloy shells with high IP ratings further ensure longevity against constant moisture and corrosive elements.

Engineers also focus on internal component protection. They utilize energy-limiting components such as zener barriers and resistors. These components restrict the energy flowing through the circuits. The design actively prevents fault conditions from generating sparks or hot surfaces. This meticulous engineering minimizes the risk of ignition in flammable atmospheres during routine operations or maintenance. Headlamps maintain circuit integrity even under extreme conditions like high humidity, intense vibration, and fluctuating temperatures.

Effective heat management is crucial for reliability. Premium explosion-proof lighting fixtures incorporate special thermal designs. These designs keep LED luminaires cool, which is vital for extended life in hazardous locations. Equipment also undergoes design for the Lowest Anticipated Service Temperature (LAST). This ensures the headlamps withstand stress from waves, wind loads, and extreme cold, such as -76°F (-60°C) in Arctic environments. This comprehensive approach to durability makes explosion-proof sensor headlamps dependable tools for worker safety.

Improved Situational Awareness Through Consistent Lighting

Consistent lighting from sensor headlamps significantly improves a worker’s situational awareness in dynamic and hazardous oil and gas environments. Situational awareness involves understanding one’s surroundings, the tasks at hand, and potential risks. Reliable illumination directly contributes to this understanding. Workers can clearly see their immediate work area, potential obstacles, and the condition of equipment.

The adaptive lighting technology in these headlamps ensures continuous, optimal visibility. As workers move or change their focus, the light adjusts automatically. This eliminates dark spots and reduces the need for manual adjustments. Workers maintain a clear view of their path and their hands, even when performing complex tasks. This consistent illumination helps them identify hazards like uneven surfaces, spills, or loose equipment before an incident occurs.

Enhanced visibility also improves interaction with complex machinery. Workers can accurately gauge distances to moving parts and identify potential pinch points. This precision reduces the risk of accidents involving heavy equipment. In emergency situations, clear and consistent lighting allows for faster identification of escape routes or injured colleagues. It also aids in the rapid assessment of a scene, which is critical for effective response.

By providing a steady and adaptive light source, sensor headlamps reduce visual fatigue. Workers remain more alert and focused over longer shifts. This sustained attention directly translates into better decision-making and fewer errors. Ultimately, the consistent lighting provided by these advanced headlamps empowers workers. It gives them the visual information they need to operate safely and efficiently, enhancing their overall confidence and productivity in challenging conditions.

Key Safety Benefits of Sensor Headlamps in Practice

Reduced Risk of Trips, Falls, and Collisions

Sensor headlamps provide continuous, direct illumination. This lighting helps workers clearly see their path. They can identify obstacles like pipes, cables, or uneven surfaces. This direct visibility significantly reduces the chance of tripping. Workers also maintain better balance. Their hands remain free to steady themselves or hold onto railings. This hands-free capability is crucial in navigating complex industrial environments. It prevents falls from heights or into open pits. Furthermore, consistent lighting improves depth perception. Workers can better judge distances to moving vehicles or machinery. This awareness minimizes the risk of collisions.

Prevention of Hand Injuries and Distractions

Workers in the oil and gas industry often perform tasks requiring fine motor skills. They handle tools or manipulate small components. Traditional handheld lights force workers to use one hand for illumination. This leaves only one hand for the actual task. This situation increases the risk of hand injuries. Workers might slip or mishandle tools. Sensor headlamps eliminate this problem. They provide constant, hands-free light. This allows workers to use both hands for their work. This dual-hand capability enhances precision and safety. It also reduces distractions. Workers do not need to constantly adjust a light source. They can maintain full focus on their critical tasks. This focus is vital when operating or maintaining complex machinery.

Faster Response Times in Emergency Situations

Emergencies in oil and gas facilities demand immediate action. Quick assessment and response are critical. Sensor headlamps provide instant, reliable illumination during power outages or unexpected events. This immediate light helps workers quickly identify the nature of an emergency. They can locate injured colleagues faster. They can also identify safe escape routes. The adaptive lighting ensures visibility even in chaotic conditions. This capability significantly improves the effectiveness of emergency response teams. It allows for rapid decision-making. This speed can be life-saving. Explosion-proof sensor headlamps are particularly vital in these scenarios. They provide safe illumination without posing an ignition risk in volatile environments.

Compliance with Industry Safety Regulations

The oil and gas industry operates under stringent safety regulations. These rules protect workers and prevent environmental disasters. Companies must adhere to standards set by bodies like OSHA (Occupational Safety and Health Administration) and API (American Petroleum Institute). Using certified equipment, such as explosion-proof sensor headlamps, helps companies meet these critical requirements.

“Without safety certified headlamps appropriate for the application, companies are exposed to potential liability if an incident occurs. By supplying workers with headlamps that are rated for any hazardous environment [that could be encountered on the job site], companies can prevent the problem,” says Colarusso.

This statement highlights the importance of providing workers with correctly rated headlamps. It directly addresses potential legal and safety liabilities. Intrinsically safe headlamps are essential for compliance. They ensure operations remain within legal and safety boundaries.

OSHA’s standard for confined spaces in construction (1926.1201 – 1213), effective in 2015, expanded the use of construction headlamps. In environments with flammable gases, vapors, liquids, materials, fibers, and dusts, OSHA mandates that equipment, including hard hat headlamps, must be intrinsically safe. Intrinsically safe products, such as industrial headlamps, are designed to reduce energy levels to prevent ignition. They are incapable of triggering combustion or igniting gases or fuels. This design allows workers to wear them around volatile substances without risking static electricity or heat discharge causing ignition. Therefore, these headlamps are not just beneficial; they are a regulatory necessity in many oil and gas settings.

Increased Worker Confidence and Productivity

Providing workers with reliable and safe tools significantly boosts their confidence. When personnel know their equipment will perform in hazardous conditions, they feel more secure. Sensor headlamps offer consistent, hands-free illumination. This reliability reduces anxiety associated with working in dark or dangerous areas. Workers can focus on their tasks without worrying about light failure or ignition risks.

Increased confidence directly translates into higher productivity. Confident workers perform tasks more efficiently and with greater precision. They make fewer errors. The hands-free operation of sensor headlamps allows workers to use both hands for their duties. This capability speeds up complex operations. Adaptive lighting ensures optimal visibility at all times. Workers do not waste time adjusting their light source. This seamless illumination keeps tasks moving smoothly.

Furthermore, reduced stress from reliable lighting improves overall job satisfaction. Workers who feel safe and well-equipped are more engaged. They contribute more effectively to team goals. This positive environment fosters better communication and collaboration. Ultimately, explosion-proof sensor headlamps enhance both individual worker output and overall operational efficiency. They create a safer, more productive workforce in the demanding oil and gas industry.

Beyond Safety: Operational Advantages of Sensor Headlamps

Sensor headlamps offer significant benefits beyond immediate safety. They enhance operational efficiency and contribute to long-term cost savings. These devices streamline workflows and simplify safety management.

Efficiency Gains Through Streamlined Tasks

Sensor headlamps significantly boost operational efficiency. Workers perform tasks more quickly and accurately with consistent, hands-free illumination. They do not need to pause to adjust their light source. This continuous visibility allows for uninterrupted work, especially in complex or confined spaces. For example, technicians can troubleshoot machinery or perform intricate repairs with both hands. This capability reduces the time required for task completion. Adaptive lighting also ensures optimal visibility for specific tasks, minimizing errors and rework. This leads to faster project timelines and increased productivity across the entire operation.

Cost Savings from Incident Reduction and Equipment Longevity

Investing in sensor headlamps generates substantial cost savings. Fewer workplace incidents mean reduced expenses related to medical care, insurance claims, and lost workdays. The intrinsic safety features of these headlamps prevent costly explosions or fires. Their robust, durable construction also contributes to savings. These headlamps withstand harsh oil and gas environments, reducing the need for frequent replacements. This longevity lowers procurement and maintenance costs. Ultimately, the initial investment in high-quality sensor headlamps pays off through enhanced safety and extended equipment life.

Ease of Training and Integration into Safety Protocols

Integrating sensor headlamps into existing safety protocols is straightforward. Their intuitive design makes them easy for workers to learn and use. Companies implement comprehensive training programs for proper usage and maintenance. These programs also cover emergency procedures and highlight the benefits of wearable technology.

Effective integration involves several best practices:

- Training Employees on Usage and Safety Protocols: Provide comprehensive training on proper use, maintenance, emergency procedures, and the benefits of using wearables.

- Ensuring Data Privacy and Security: Implement robust data protection measures. Inform employees about data collection. Collect only necessary data. Regularly delete obsolete data. Change default passwords and enable multifactor authentication. Encrypt and store data securely. Comply with privacy laws.

- Best Practices for Data Collection and Analysis: Define the purpose of data collection. Gather only necessary data. Regularly calibrate sensors and verify data accuracy. Anonymize data and follow data protection regulations.

- Analyzing Data for Long-term Safety Improvements: Continuously review and analyze data. Identify patterns and trends. Work with experts to interpret insights. Use data to inform training and process improvements.

- Using Predictive Analytics to Prevent Accidents: Create and refine predictive models. Base these models on historical and real-time data. Integrate analytics into safety management. Use insights to proactively address risks.

These steps ensure seamless adoption and maximize the safety benefits of sensor headlamps.

Sensor headlamps are a fundamental safety tool in the oil and gas industry. They directly contribute to a safer, more efficient, and compliant work environment. Their advanced features, including intrinsic safety and adaptive lighting, make them indispensable for protecting personnel and assets. Investing in these devices is critical for mitigating risks and optimizing operations in hazardous environments. These systems offer real-time monitoring and enhance worker safety. They also increase operational efficiency, leading to significant cost savings. Furthermore, they support environmental compliance and foster a proactive safety culture.

FAQ

What makes sensor headlamps “explosion-proof”?

Explosion-proof headlamps feature intrinsically safe designs. They prevent sparks or heat capable of igniting flammable gases or vapors. Certifications like ATEX, IECEx, and UL Class I, Division 1 confirm their safety for hazardous zones. This design protects workers and prevents catastrophic incidents.

How do sensor headlamps improve worker safety?

They provide hands-free, adaptive lighting, reducing trips and falls. Workers use both hands for tasks, preventing injuries. Consistent illumination enhances situational awareness, allowing faster emergency responses. This technology directly contributes to a safer work environment.

Are these headlamps compliant with industry regulations?

Yes, certified explosion-proof headlamps meet stringent industry standards. They comply with regulations from bodies like OSHA and API. This ensures operations remain within legal and safety boundaries. Companies avoid potential liabilities by using compliant equipment.

What operational benefits do sensor headlamps offer beyond safety?

They streamline tasks, increasing efficiency and productivity. Companies save costs through reduced incidents and equipment longevity. Their easy integration into safety protocols simplifies training and management. These benefits contribute to overall operational optimization.

How does adaptive lighting technology function in these headlamps?

Adaptive lighting adjusts brightness and beam patterns automatically. It responds to ambient light, worker movement, and specific tasks. This ensures optimal visibility without manual adjustments or glare. Workers maintain focus and perform tasks more effectively.

Post time: Nov-10-2025

fannie@nbtorch.com

fannie@nbtorch.com +0086-0574-28909873

+0086-0574-28909873